Aptella has signed an exclusive distribution agreement with Blue Electronics for its range of personal proximity and machine proximity detection systems. Aptella has been appointed the exclusive distributor for Blue Electronics’ range of collision avoidance and proximity detection systems, personal proximity detection systems and sound alarm monitoring systems. Blue Electronics premium range of personal proximity and machine proximity detection systems includes: Personal Proximity Detection Systems (PPDS);Vehicle to Vehicle Collision Avoidance Systems (VCAS);Tyre Handler Personal Proximity Detection Systems (PPDS);Stockpile Dozer and Stacker Machine Collision Avoidance Systems (SCAS);Early Warning Detection Systems (EWDS) for Rail Maintenance MachinesEnd Of Train Detection Systems (EOTS);Trackside Warning Systems (TWS);Web-based GPS Tracking Systems (GPS);In Vehicle Monitoring Systems (IVMS);Sound Alarm Monitoring Systems (SAM).These systems are suitable for

Using a machine guidance system, such as Aptella’ Carlson LandfillGrade, can help landfill site operators increase the efficiency, productivity and safety of their landfill site. “The Carlson LandfillGrade machine guidance system helps our customers improve the efficiency and safety of their landfill sites through the maximisation of vertical space, leachate management, avoidance zones for gas wells and hazardous material placement and access to better, more accurate data,” said Andrew Granger, Product Manager: Mining and Landfill Systems at Aptella. Maximise vertical space This solution from Aptella assists landfill site operators to maximise the void space of their landfill site through optimised compaction and increased density. Brad Wood, Operations Manager and Oscar Gallagher, Operations Coordinator at the Summerhill Waste Management

Cameron Waters, Geospatial Business Manager, Aptella To truly unlock your software and the earning potential of your surveying company, there is five key criteria to consider when you partner with a software company before you even get to the nuts and bolts. Digital surveying requires integrated solutions. Surveying data processes are changing and the isolated data of old, needs to evolve into the collaborative multi-disciplinary models of today. The MAGNET workplace is the home of collaboration and has transformed the workflow and value of surveying software. MAGNET is now providing simpler, comprehensive, high value products to meet the multi discipline survey workflows of today. Are you getting the best from your software provider? To find out, consider the following five key criteria:

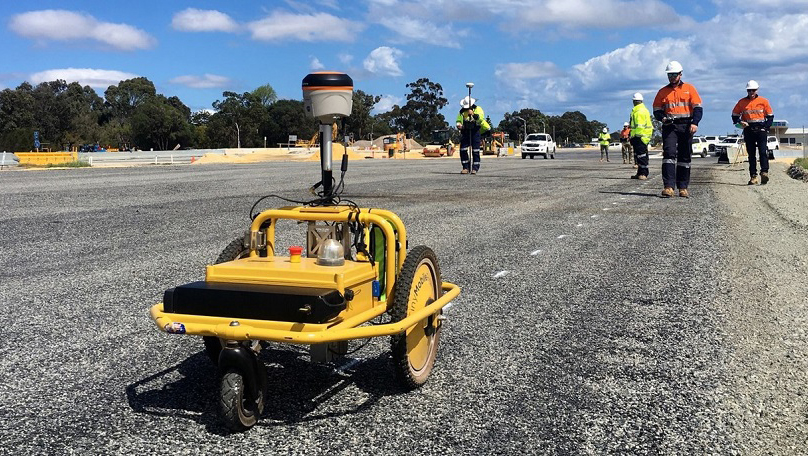

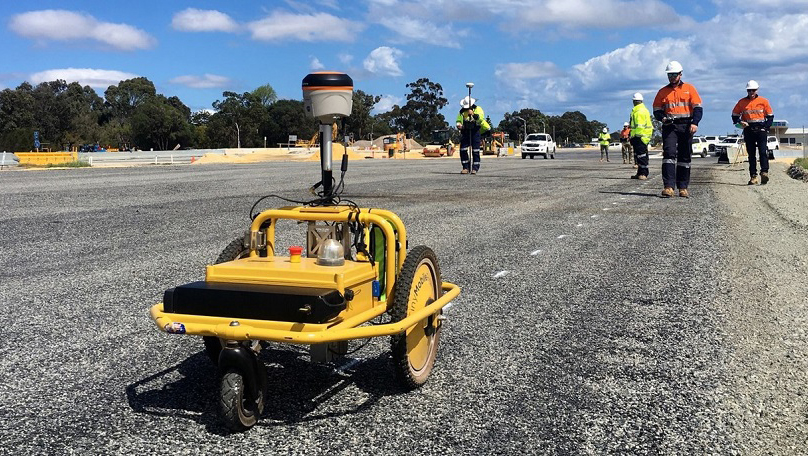

Cameron Waters, Business Manager – Geospatial Systems, Aptella The construction industry has the lowest productivity and the most amount of rework. So, while the manufacturing, mining and farming industries are all increasing productivity, the construction industry is doing the opposite. So, let’s talk solutions Technology and automation are no longer the future of infrastructure: they are the present. It’s not often that a solution comes along that can improve a workflow so dramatically that it improves all critical performance factors: safety, productivity and quality, not by 5-10% but by 500-1,000%. During the construction of a road there are several line marking tasks that are traditionally done by a surveyor. With the change to a digital construction model the

Proximity detection systems can increase safety on site by alerting machine operators, drivers of light vehicles and individuals on foot to their proximity to other workers on site via small devices fitted to the machine or worn on clothing. Collision awareness technology alerts operators to collisions, either with other machines or assets such as coal valves, stacker and reclaimers on stockpiles when they enter an avoidance zone. Since the technology’s inception, proximity detection and collision awareness solutions have become both more sophisticated and easier to use. Historically some systems have been known to ‘over alarm’ or be very complex to install and manage, becoming a hinderance to productivity. This ‘boy who cried wolf’ situation can lead to more