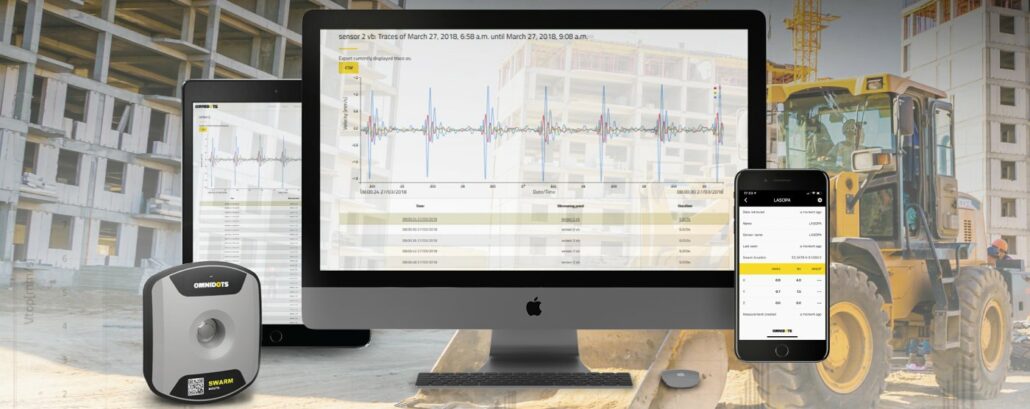

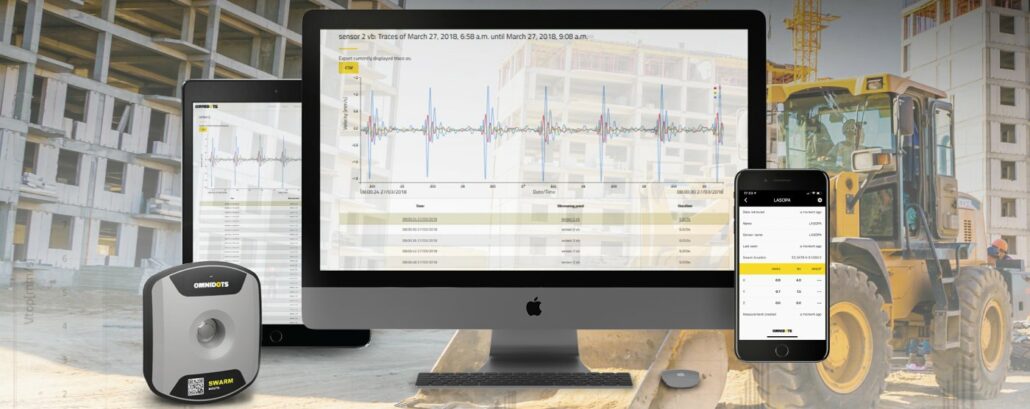

Intelligent positioning solutions provider Aptella to distribute Omnidots’ innovative wireless vibration monitoring platform throughout Australia and New Zealand. Omnidots specialises in easy to setup, autonomous, reliable vibration monitoring systems for use in infrastructure and geophysical applications. Under the agreement, Aptella has been appointed Master Distributor for the Omnidots range. “The Omnidots solution is unique in its capacity to deliver a fully automated, wireless, and integrated vibration monitoring platform that can be installed and setup in minutes,” said Andrew Jones, Monitoring Marketing Development Manager at Aptella. “The Omnidots range compliments our other deformation monitoring solutions and has already received very positive feedback from customers using it for commercial construction and infrastructure projects,” he added. Vibration monitoring is important in

Did You Miss Our Webinar? Don’t Worry, You Can watch Our On-Demand Webinar In this webinar, you’ll learn how Pix4D’s new geospatial solutions – Pix4Dmapper, Pix4Dmatic and Pix4Dsurvey – can help to optimise the surveying and mapping workflows to achieve accurate results and get the relevant information your team needs. Key topics: – Photogrammetry pipeline: processing your data into accurate point clouds, digital surface models (DSM) and orthomosaic – Creation of engineering-ready CAD files from photogrammetry projects – Different user cases – Q&A session Acess On-Demand Webinar Limited Time Offer – Free training and certification FREE Online Training And Certification With A 12-Month Pix4Dmapper Subscription! SAVE NZ $600 Request More Info

The National Measurement Institute (NMI) advises that industrial scales should be calibrated every 6-12 months depending on the stresses applied to the scale, or after major hydraulic work is completed on the scale. This is for maintaining accuracy, fairness, and to comply with regulations that could otherwise cost you. Maintaining accuracy No matter how robust your industrial scale is, over time it becomes less accurate from natural wear-and-tear. Maintaining accuracy is important for both trade and non-trade purposes, including adhering to the load bearing capacity of a machine, or ensuring you have enough of a certain material for a construction project. When measuring large quantities of material, even a small discrepancy in the scale’s accuracy can result in

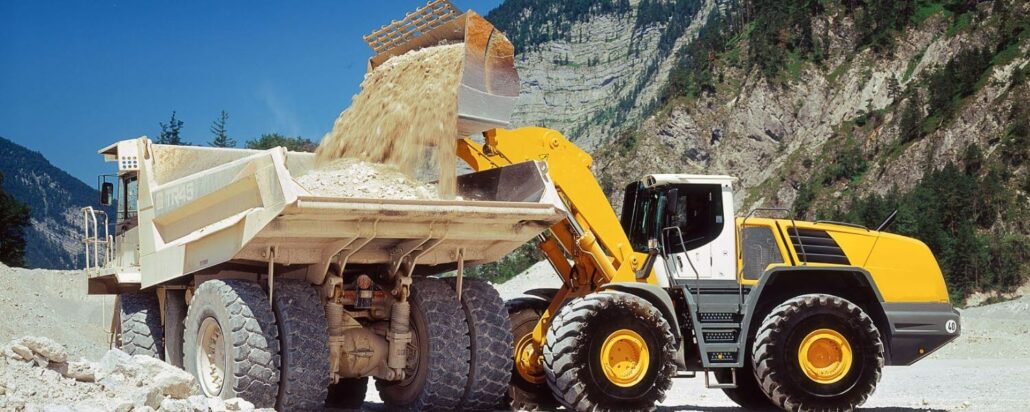

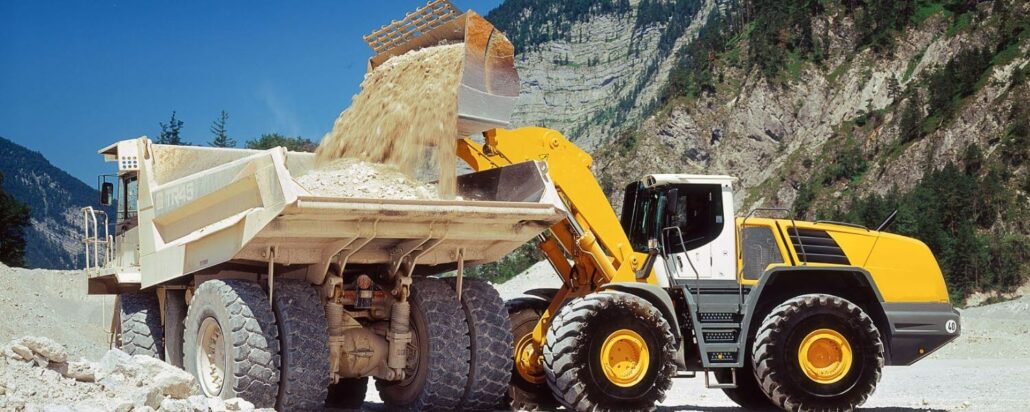

Machine operators, port workers, garden centre managers, and anyone who works with a loose material should be aware of the types of scales available to them, which are suitable for their needs, and what their requirements are. Learn more about the types of scales and which you should upgrade to below. Front end loader scales Front end loader scales are weighing systems built into the loaders’ hydraulic lift lines and feature an easy-to-read visual display. With front end loader scales, operators can determine the weight of the load simply by lifting the bucket at a constant lift speed, rather than having to drive to the weighbridge, stop, and turn around if loaded incorrectly. Weighing loads on front end

Legal trade and non-legal trade scales both have regulations and rules at the manufacturing level, and each have their potential upsides and drawbacks to discuss before purchasing, calibrating, or re-calibrating them. But how do they affect you? Legal trade scales Legal trade scales or ‘trade-approved’ scales are industrial scales used to determine how much someone pays. This can be in a commercial setting, or to calculate a tax, toll, remuneration, bonus, tariff, or penalty. If you are using a scale for this purpose, or for lawmaking or medical purposes, trade measurement law dictates that you must use a legal trade scale. These are scales which could have detrimental effects on the general public if inaccurate. Legal trade scales

Intelligent positioning solutions provider Aptella to distribute Soil Instruments’ geotechnical sensor range for specialised monitoring applications throughout Australia and New Zealand. Soil Instruments designs and manufactures a wide range of geotechnical monitoring instruments that are used to detect variations in pressure, strain, settlement, or other parameters in deformation monitoring scenarios. “Aptella has worked with Soil Instruments’ product range for 18 months for specific projects that have required specialised sensors,” said Andrew Jones, Monitoring Marketing Development Manager at Aptella. “Soil Instruments has an excellent reputation amongst engineers and geotechnical specialists for their high quality monitoring products,” he added. “Their range expands our monitoring solution portfolio, providing customers a more efficient technical and commercial offering,” he added. For almost 60

iDig is a simple 2D excavator system that gives the operator a live position of the bucket to guide them to grade quickly and accurately. It works with all makes, models and sizes of machine from little one tonne diggers up to mine excavators. Wayne Nicholson, owner and operator of Combined Excavations, explains they have the iDig system fitted to their two 1.5 tonne and 13-tonne excavators. “We utilise the 2D system to save us time on the ground as well as labour costs,” Mr Nicholson said. iDig helps operators get to grade in a range of applications, including slopes and levels, whilst providing real time information on the position of the cutting edge. It removes the need

As an everyday practise, we have seen industrial services adopt the use of drones. Whether it is to accurately survey a construction site or to inspect remote infrastructure, drones in the construction industry have become increasingly popular as a way of safely and accurately getting field data to inform decisions on site. Drones have become increasingly popular in support of mining applications with exploration, surveying and mapping. Australia and Africa have led the way in adoption of unmanned aerial vehicles (UAVs) across their mining industries to maintain safety, increase oversight and enhance security. As an everyday practise, we have seen industrial services adopt the use of drones. Whether it is to accurately survey a construction site or to