Mt Carlton is located 150km south of Townsville, Queensland. Operating a 500-metre by 400-metre pit and a 600-metre by 600-metre tailings dam, the company opted to introduce advanced deformation monitoring technology to deliver real-time status updates and alerts to its team.

Evolution opted for Senceive’s GeoWAN solution, a long-range transmission system capable of covering areas up to 15-kilimetres. It incorporates several sensors placed along the tailings dam and/or pit walls to measure for minute movements in the surface. The sensors are wirelessly connected to a solar powered gateway, positioned near to the pit, where data is transferred live to the web-based monitoring software.

Depending on the application, different sensors can be used in combination to deliver highly accurate geotechnical measurements, including tilt, pressure, vibration, temperature or optical displacement.

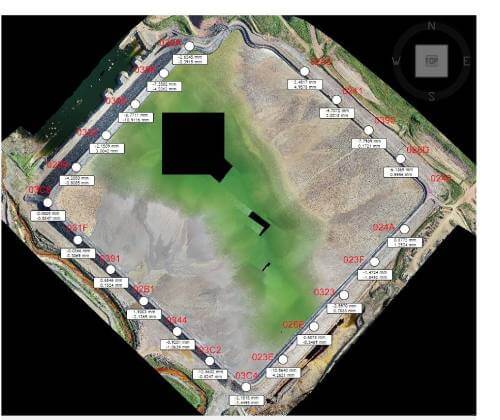

The setup at Mt Carlton

At Mt Carlton, Evolution has more than 20 triaxial tilt sensors positioned around the tailings dam to measure for any movement. The team is also rolling out live monitoring of piezometers that measure changes moisture levels within the tailings dam walls.

In the open pit, there are numerous sensors monitoring pit wall, waste backfill and survey pillar movement.

Senior Mine Surveyor for the company, Callum McNaughton, said the solution has enabled his small team to provide accurate, viable deformation monitoring data to the departments that need it.

“The wireless monitoring platform has been perfect for us,” he said. “It dramatically reduces the need for us to manually survey these areas, saving us time and increasing safety by removing surveyors walking these areas on foot.”

One of the key advantages of using this deformation monitoring technology, Mr McNaughton explains, is the ability to set different tolerances and time triggers for each sensor and/or area.

“In the tailings dam we have a slightly higher tolerance before any alerts are triggered, because you do get some movement in the dam and swelling from rain,” he said.

“Inside the pit and in one area where there is a crack in the wall, the tolerance is much tighter and the sensors are triggered more frequently,” he added. “The sensors are also firing measurements every 10 minutes in the pit, whereas they monitor every half an hour on the tailings dam.”

Team collaboration

The deformation monitoring data is used by multiple teams at Evolution Mining, including surveyors, geotechnical engineers, pit supervisors and the control room. “We can configure who gets the alerts and the escalation process, so that different teams can receive different levels of alert if need be,” Mr McNaughton said.

In addition to alerts if movement outside of tolerance is detected, the team uses the monitoring information for various reporting requirements. Geotechnical and survey teams use the data in their monthly reports, and it also forms part of the company’s quarterly compliance report for the tailings dam.

“It’s great that the monitoring data is helpful to so many different stakeholders at Evolution,” Mr McNaughton said. “The geotechnical engineers can pull out any relevant information for their reports and dashboards, and the pit supervisors can instantly receive any alerts if there are changes detected by the system.”

Support from Aptella

Technical support and product training is provided by Senceive distributor, Aptella. The deformation monitoring team offers comprehensive advice, installation, onboarding and support throughout Australia, New Zealand and South East Asia.

“Having a local team was crucial for us to ensure that any technical issues could be actioned quickly,” Mr McNaughton said. “The Aptella team has provided excellent communication and fast turnaround times whenever we have needed help. Initially we relied on the support team a lot as we learnt how to configure and use the technology, but once we had everything setup the way we wanted it was more a case of configuring our internal processes and escalation procedures if alerts are received,” he added.

Complimenting a surveyor’s work

Mr McNaughton said that the wireless monitoring system did not replace traditional survey methods, but instead complimented them with ongoing monitoring data that enables early intervention and proactive management of the pit and tailings dam.

“The platform doesn’t take away from a mine surveyor’s work, it acts as a pre-warning system and enables us to track trends over time. In my opinion, the reliability, longevity and accuracy of the system we have in place at Mt Carlton would be hard to beat,”

Callum McNaughton

We source, deploy and support intelligent positioning solutions to enhance our customers’ productivity.

Aptella Pty Ltd

ABN 56 130 367 065

2024 Aptella Pty Ltd | ABN 56 130 367 065 | Terms and Conditions | Privacy Policy